Computer Won't Turn Back on After Shutdown Procedure

Imagine creating a poster, book cover or business card that lights up when you say "Hello." Think you could print that out on a regular printer without any electronics or programming know-how? You can, if you have PaperPulse.

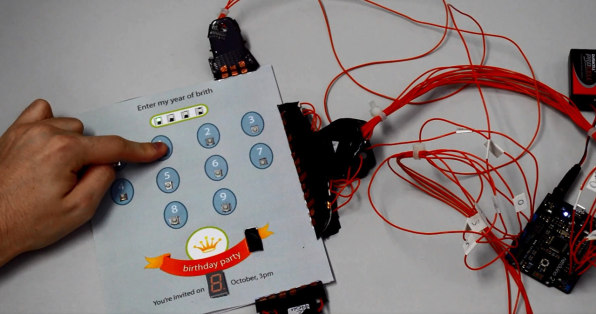

With the aid of a conductive ink printer cartridge, this revolutionary software lets you to fashion and print interactive designs on your home printer, supplemented by a few electronic components such as LEDs and microcontrollers. The technology has all sorts of potential applications in interaction design, from smart packaging to, yes, blinking business cards.

PaperPulse came into being when researchers at Hasselt University iMinds in Belgium asked themselves if they could design a tool for visual designers to create functional paper electronics without any technical skills. It had to be something that designers could operate easily, dragging and dropping familiar elements like widgets, and it had to generate the programming logic on the backend for all the components to work properly. "We were interested in how we could make the design and fabrication process of interactive paper as easy as using design tools like Photoshop and illustrator, tools that designers are comfortable with," says Raf Ramakers, a PhD Student on the team.

There have been plenty of advances in printed electronic circuitry. University of University of Tennessee researchers developed a special nanoparticle-based ink to create durable printed circuits, and Georgia Tech scientists highlighted a technique to get inkjet printers to produce functional circuits faster. But PaperPulse is different because users simply demonstrate what they want the paper to do, then leave the software to handle the rest.

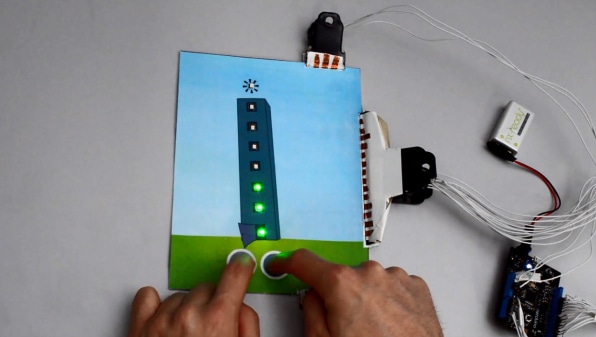

Put another way, PaperPulse doesn't make designers write code. Instead, it has a Photoshop-like interface that lets designers specify the logic between components. To start with, the users simply add interactive elements like push buttons, sliders, LEDS, and microphones to the design they are working on. If they need an LED to light up only when a button is pressed, they begin recording that action–they demonstrate the button click in the canvas and set the LED to the appropriate brightness. Or if they add a slider, they demonstrate how the brightness of the LED changes according to the slider's value.

The software automatically generates the necessary code for the recorded demonstration, which the user can test out and debug in a simulator. PaperPulse can also infer logical actions and offers suggestions. Take the LED example, for instance. The software might suggest turning the LED's brightness back to zero, once the button is released. Users can use additional dialog boxes to fine-tune the recorded demonstrations and get the timing right; they can specify for instance, whether a set of recorded actions have to happen simultaneously or one after the other. "It makes it a lot easier for designers to specify logic this way since they can directly demonstrate all actions in the context of visual design elements on the canvas and don't have to write code in a separate editor," Ramakers says.

Once the design is complete, the designer specifies the microcontroller's position. The software begins the printing process by generating electronic circuits that connect widgets to pins on the microcontroller and a PDF file that contains the circuits, cut and fold lines, and other visual elements.

The user prints out the PDF on ordinary paper using an inkjet printer filled with conductive ink and follows step-by-step instructions in a customized tutorial to cut, fold, and glue the interactive papers. Stickers can be used to bridge intersections that the software couldn't automatically connect and also to connect components like LEDS, microphones, and buzzers. Finally the user attaches the microcontroller and uploads the programming code generated by the software directly onto the microcontroller via a USB cable. Add a battery to the end result and voila! You have an interactive paper gizmo.

Using PaperPulse, novices were able to create interactive paper products like a diet card that tracks what you eat and a poster that responds to the intensity of music in the environment, in about 45 minutes. You could even enrich packaging material with dynamic content, Ramakers says, like adding countdown timers to highlight expiration dates or adding simple games to cereal boxes. Think of interactive book covers, postcards, and placemats.

"It allows the end-user to add physically rich interactions to paper, such as touching, swiping, pulling, pushing, etc," explains Ramakers. "We believe that we can reveal the true potential of this new technology by allowing many people to build interactive paper artifacts."

It's also ridiculously inexpensive to do. Printing with conductive ink is equivalent to printing with regular ink, and a single cartridge can print out a few hundred sheets. Most of the electronic components used cost only a few cents, so if you don't like a design you can simply scrunch it up and throw it away.

Currently it's only possible to connect around 15 electronic components to a microcontroller since each element requires one of its connection pins but the team plans to work on multiplexing strategies next. This will allow multiple components to share one microcontroller pin, which let you add more components (and create more complex designs).

"We see the prototypes that we designed with PaperPulse as 'hello world' examples in the design space of interactive paper," states Ramakers. "When regular sheets of paper can be made interactive by augmenting them with basic, cheap, electronic components, like buttons, sliders, LEDs, microphones, segment displays, buzzers, switches, etc. you can envision a future where every paper in the world has some interactive capabilities."

The team comprising of Raf Ramakers, Kris Luyten, and Kashyap Todi have filed a patent related to PaperPulse and hope to have it out in the market in due course. They will be presenting PaperPulse at the ACM Conference on Human Factors in Computing Systems (CHI 2015) in Seoul, South Korea, this week.

Computer Won't Turn Back on After Shutdown Procedure

Source: https://www.fastcompany.com/3045220/amazing-software-turns-paper-into-computers